OUR TOWERS

QUALITY

CONSTRUCTION

EVERY STEP

OF THE WAY

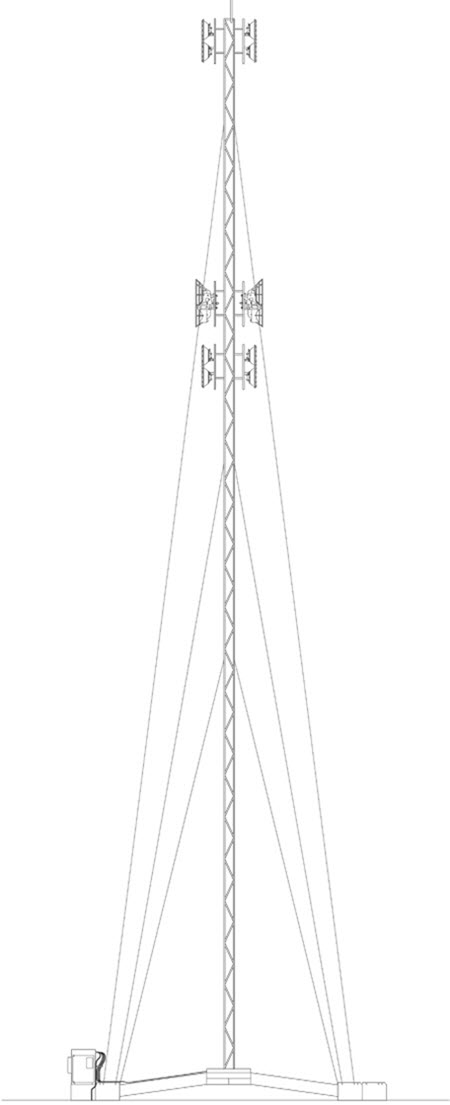

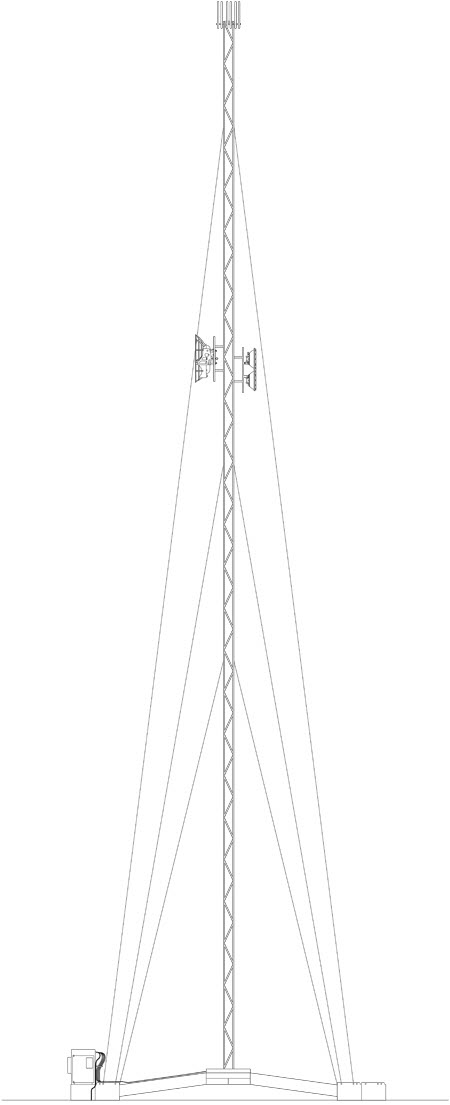

A uniquely designed, cost effective and high-efficiency Non Ground Penetrating Self-Supporting Antenna System

Tower structures, commonly used for supporting a variety of equipment, typically employ a foundation anchored into the ground below (such as pouring concrete piles), to resist overturning forces. Because ground conditions vary greatly, the process usually requires costly and time consuming design requirements for each individual site, as well as regulatory permits and hurdles.

These specially manufactured towers do not require penetration into the ground and overcomes these obstacles

Ballasts secure the structure base to the land below. Guy-wires are connected between the support tower and the tower base. The arrangement of the frame members provides a frame assembly that can be constructed from modular units, which provides lower costs and efficient transport and assembly on site.

ABOVE GROUND

ENGINEERING.

Incorporating a base, coupler, and tower of up to 100 ft. in height with the following capabilities:

- Non-ground penetrating design

- Modular design (individual part < 140lb) to allow for ease of assembly/disassembly

- Withstands 5,000 lbs of non-dynamic force and unknown dynamic force

- CSA-1 and CSA-3 wind load rated

- Ease of assembly and disassembly

100ft tower height:

- Exceeding 3,000lbs pressure of upward lift

- Exceeding 8,000lbs downward dynamic pressure

- Capable of being transported and placed on location by helicopter if necessary

FAST AND EASY

INSTALLATION.

The base of the tower is self-supported on a ground surface using three ballast material receptacles spaced radially outward from a central tower coupler that pivotally supports the bottom end of a tower frame. The ballast weights are 90 lbs. The heaviest frame piece is only 140 lbs and requires only 2 handlers.

That connection between the support tower to the base, allows lifting equipment to be attached without a crane or boom truck being required, representing a significant cost saving over typical tower constructs.

The lifting kit includes a lifting strut and a winch, and once the support tower is erected into place threaded fasteners affix the tower to the base.

The frame of the support tower comprises 3 columns, and the horizontal spacing is gradually reduced from the bottom end to the top end. All three are connected to a ballast receptacle.

Struts are interconnected to create a trust structure of the tower frame, and suitable brackets protrude outward to support communications antennas. Mounting, support and brace plates secure the structure.

The assembly of the tower typically involves transporting the central frame portion of the tower base, the frame members of the base, and various modular sections of the support tower frame as separate modular components to the installation site.

GREAT

VALUE.

BIGSKY has initiated a financing program available for all qualified buyers, to assist in the growth of your business.

All pricing includes the modular tower components, shipping and taxes, as well as sub-contracting if required.

Our towers are built to work, built to last, and built for your success.”

BACKBONE

LAST MILE

QUALITY.

EXPERIENCE.

WORKMANSHIP.